Care and Maintenance of Your Whiteboards and Chalkboards...

Care and Maintenance of Your Whiteboards and Chalkboards

When I joined the visual display board industry in 1994 there were two US manufacturers of porcelain steel chalk and marker writing surfaces. One located in Harrison, AL and the other in Alliance, OH. It was convenient to visit AllianceWall since I resided only 40 minutes away. An FYI, the AllianceWall manufacturing operation was acquired by Polyvision and a few years later was relocated to Okmulgee, OK.

After a few visits I’ll share with you what I learned. First, the descriptive term of “porcelain enamel” is popular but the actual industry term is “vitreous enamel”. Vitreous (Latin vitreum, meaning “glass”) enamel is powdered glass combined with other raw materials including silica sand (frit) that create the enamel solution. The frit is important as it creates an irregular surface texture that catches and holds the chalk or marker ink on the surface. Writing on a smooth surface, the chalk stick would pass over the surface without a mark and the marker pen ink would simply bead up.

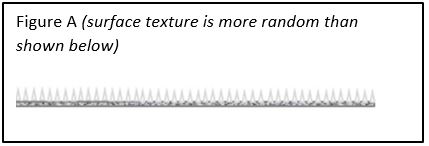

I mention this because if you were to look at a chalk or marker writing surface under a microscope you would see the peaks and valleys (refer to Figure A) even though it is relatively smooth to the touch, especially with marker surfaces. The valleys hold the chalk or ink until it is wiped away.

In addition to frit to create the irregular surface texture, some surfaces such as glass marker boards or dry-erase wallcoverings use a corona treatment to modify the surface to the desired texture. The process treats the material with a high frequency corona discharge giving it an adhesive property so the dry erase ink will hold to the surface. All writing surfaces require the irregular surface to catch and hold chalk and ink and perform well with chalk or markers.

Marker pens use a “carrier” solvent to transition the pen’s reservoir of ink from the pen to the writing surface. A dry erase marker uses an oily silicon polymer solvent. Even after erasing the dry erase ink from the markerboard, a portion of the solvent may remain on the board’s surface. Left to build up on the surface, these solvents will impair your board’s performance. You may not be able to see it until your board is difficult to properly erase.

Why is this important for your understanding before we explore the care and maintenance of your chalk and marker boards? If you don’t regularly and properly clean the chalk or marker surface, the chalk or ink solvent held in the “valleys”, will build-up over time (refer to Figure B) and will negatively impact the performance of your writing surface. The longer this residual chalk or ink solvent remains, the more difficult it is to erase. This can be true with any writing surface whether porcelain or otherwise.

Let’s talk about how we can prevent this from happening or what you may be able to do if it does.

Troubleshooting Performance Issues with Your Chalk and Whiteboards

The most common issue raised among those using whiteboards is the ghosting, or residual marker ink remaining on the surface after erasing. Typically, the ink is trapped in a film or residue remaining on the writing surface itself. Fix: Do a thorough cleaning with a whiteboard cleaner. Use a clean towel to dry the surface.

Dirty or Wrong Erasers – when using the wrong or dirty eraser, erasing only buries the ink solvents deeper into valleys and causes ghosting. Fix: The best eraser I’ve found is a Microfiber towel. They pull the dry ink away from the writing surface and are easily cleaned for reuse. Make sure erasers are routinely switched out with a clean eraser to ensure a good writing and erasing surface at all times.

One other item to note. When permanent marker is used on some of the better-quality marker surfaces, tracing over the permanent marker writing or marks with a dry-erase marker will break down the permanent marker ink and the writing or marks will wipe off.

“Wet” erasing – this is when the marker ink is erased prior to the ink fully drying. A clean cloth may not pull from the surface the yet to dry solvent leaving a residue that will cause ghosting. Fix: Resist the temptation to immediately wipe and allow the ink to completely dry before erasing.

The main issue with chalkboards has always been the chalk and binder settling into these surface valleys and hardening to where the surface becomes so smooth, the chalk no longer is captured by the surface and the chalk stick slides across the surface leaving either a partial mark or no writing.

Fix: If your chalkboard is a composition or painted surface you may need to replace the board. If you’re troubleshooting a porcelain chalkboard there is a possible answer. Find a cleaner known as Bar Keeper’s Friend and use a medium bristle brush to scrub the surface. Use fresh and clean water rinse the board after scrubbing it down. You may have to repeat a few times, but you will find this technique can prolong the use of your board.

New chalkboard surfaces can have a temporary ghosting problem, as well.

Fix: Manufacturers recommend that you “break in’ your new chalkboard. Take a quality chalk stick and rub the side of the stick over the complete surface and erase – twice. This will condition the entire surface so the first few times you write on the board it won’t ghost. If you do nothing, eventually through continued usage, the surface will break itself in.

Your economical chalkboard is getting scratches everywhere. Fix: The binder agent used to bind the chalk into a stick form is very important. With some chalk the binder can be very hard, so hard the stick may scratch a painted chalkboard surface or may not even release the chalk as you write. Always buy a quality chalk to maximize the longevity of your chalkboard.

Care and Maintenance of Your Writing Surfaces on a Routine Basis

How to Clean a Whiteboard

Just about every brand of visual display boards will have care and maintenance instructions along with your new board. Following their instructions will ensure great writing and erasing performance as well as add longevity to your board. During my nearly 30 years in the manufacturing of visual display boards, it was apparent that most people do not follow these instructions. Therefore, in lieu of recommending instructions I’m providing the links below where you can find the care and maintenance instructions for the various brands sold through Shiffler Equipment Sales. If you have not maintained your boards per the manufacturers’ instructions, I would recommend downloading these instructions and following them:

Marsh by Polyvision - Porcelain Steel Marker and Chalk Boards

Ghent Manufacturing - All Visual Display Boards

Claridge Products - LCS Markerboards

Claridge Products - Melamine Whiteboards

Claridge Products - Porcelain Steel Chalkboards

Our Recommended Cleaner to Use with Your Whiteboards - GREENCLEAN

Shiffler is introducing their new whiteboard cleaner, GREENCLEAN powered by Shiffler! This whiteboard cleaner has been specifically developed for heavily used whiteboards in schools and in the hospitality industry. Our formula cuts through the buildup on writing surfaces, as we have discussed, and leaves nothing but a clean surface, ready for more use. It's designed to work with all whiteboards from film to ceramic. What makes Shiffler’s whiteboard cleaner better? It’s environmentally safe! And that’s important when using in a classroom, kitchen, or any area where indoor air quality is important. It’s water-based eliminating fumes. Look for upcoming promotions on all Shiffler GREENCLEAN products! And where can you buy a whiteboard? Check out our full line here!

Bill Singhaus, Visual Display Category Manager for Shiffler Equipment Sales, has nearly 30 years working within the visual display board industry.